News

E-mail: sales@wodetec.com Consult

-

222022.02

222022.02Factory supply bentonite slurry grout batching plant

wodeFactory supply bentonite slurry grout batching plant combine to perform highly efficient and low consumption tasks, effectively reducing complex procedures and long distance operations. Factory supply bentonite slurry grout batching plant performs high-speed pulping production and storage of cement slurries and other similar materials, then pumps the slurries directly to construction connection points to complete uninterrupted grout. Factory supply bentonite slurry grout batching plant are primarily used in the construction of roads, railroads, hydropower, construction, mines and other above-ground and underground projects. Quickly mix water, cement, sand, bentonite, fillers, clay, silicates and other media. Then use the filling grout mixers and pumps on sale for grout injection / grout injection to provide waterproof plugging, tunnel lining, foundation and rock formation reinforcement, and gap filling functions. Continuous grout mixers and pump systems have the advantages of compact construction, high grout pressure, and wide range of applications. The performance and quality of factory supply bentonite slurry grout batching plant play a decisive role in the safety, quality and efficiency of grout projects. If the choice of grout mixer and pump system for filling is blind and arbitrary, it is relatively expensive and can fail to achieve the expected results or cause engineering...

READ MORE -

212022.02

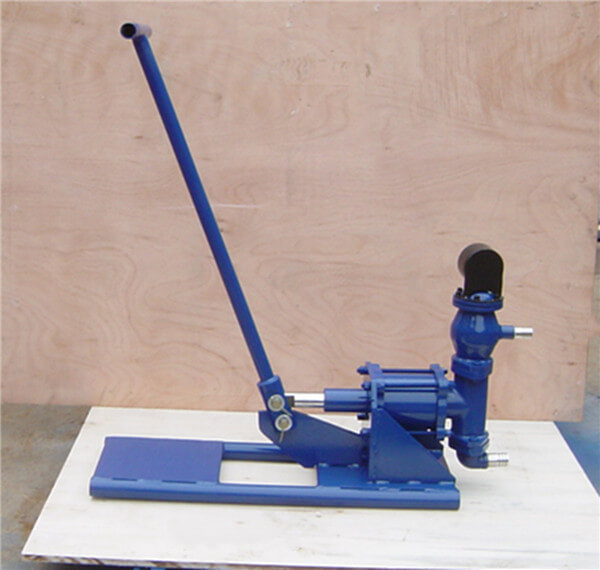

212022.02Best choice hand operated cement grouting pump

wodeBest choice hand operated cement grouting pump are versatile and can be used to inject various low viscosity fluid slurries such as pure cement slurries and chemical slurries. The hand operated cement grouting pump can solve grout mainly in special places where power is inconvenient, such as explosion-proof places, tunnels, mines, and highways. The performance of manual grout pumps on the market is stable and reliable. The hand operated cement grouting pump design and construction is simple and easy to use, and easy to clean and maintain. The hand operated cement grouting pump has the following features: No need for electricity, small size, light weight, easy to move Simple structure, durability, simple maintenance Manual operation, high pressure, grout injection speed and flow rate can be controlled arbitrarily. The following points should be noted when selling hand operated cement grouting pump: Before selling the manual grout pump, apply an appropriate amount of grease to the living hinge of the rocker and shake the handle at a constant speed to use the handle flexibly and prevent corrosion. If you find that the fasteners are loose during use, tighten them properly in time. To prevent damage to the parts, use force when swinging the handle. The joints of...

READ MORE -

182022.02

182022.02Highway Construction Shotcrete Machine for sale

wodeHighway Construction Shotcrete Machine for sale also widely used in engineering construction, mining, tunnels, calverts, subways, hydropower projects, underground projects and coal marsh mines.

READ MORE -

172022.02

172022.02Wear-resistant steel line pan type castable mixer sales

wodeWear-resistant steel line pan type castable mixer sales are easy to move, fast mixing speed, high homogeneity, compact structural design, comfortable supply height, large fireproof mixers have high mixing efficiency and low maintenance cost.

READ MORE -

162022.02

162022.02Advanced hot sell cement grout mixer machine

wodeAdvanced hot sell cement grout mixer machine are mainly driven by electric motors. The pulp is sucked into the vortex from below and sprayed from the top of the barrel to create a high speed liquid flow, creating a strong vortex in the barrel and stirring the dry powder and water perfectly evenly. To achieve lower water adhesive preparation than slurry. Compared to popular colloidal grout mixers on the market, Australian colloidal grout mixers are characterized by faster pulping rates and more uniform slurry mixing. It is one of the important facilities of a large-scale pulping station. Advanced hot sell cement grout mixer machine are mainly used to mix and prepare slurries that need to be strongly mixed in advance, such as cement slurries. It is used in grout equipment for pressure grout construction such as railroad and road construction, mining, hydropower engineering, insulation, waterproofing, grout of building foundations. Advantages of hot sell cement grout mixer machine: Highly efficient and large reserves that can be applied to various grout injection engineering operations. Safe and reliable; the key component motor has a high level of protection. The mixing arm of the storage tank adopts high strength, strong force, deformation-free, modified frame structure. High...

READ MORE -

152022.02

152022.02High efficiency Hydro semoir for sale

wodeHigh efficiency Hydro semoir for sale also known as hydraulic spray seeders or hydraulic spray seeders, use a liquid state principle, also known as sowing, and centrifuge with a certain percentage of water, fiber coatings, adhesives, and fertilizers. A pump is used to pump the mixed solution to the soil and sow it through a hose to form a uniform coating. So what are the characteristics of hydraulic atomizers? High efficiency Hydro semoir for sale today introduces the performance characteristics of Hydrose moir. Especially suitable for 3D net cover, it can be molded once. At the construction site, by adding an appropriate amount of soil according to the situation of the site, the amount of paper fiber and wood fiber can be reduced, the construction cost can be significantly reduced, the construction speed can be accelerated, and the germination rate of grass can be reduced. And seeds that can effectively improve survival. The overall price of Hydro Semoir is determined by the double diesel engine, which has separate mixing and output, high lift and high efficiency. It can be used not only for greening and spraying large areas of highway slopes, railroad slopes and reservoir dams, but also for spraying paddy fields,...

READ MORE