WGP400/1000/95/165DPL-E/A 95L/min 16.5MPa electric fully automatic grout mixer and pump

Description:

WGP400/1000/95/165DPL-E/A Grout Mixer and Pump are integrated with a screw feeder, mixing, agitator and horizontal hydraulic pump. It is mainly used to be made such as cement slurry or bentonite slurry, etc., for injecting in the sub-soil for soil consolidation, piling or even for long transport of material.

Compared with the traditional grout mixer and pump machine, WGP400/1000/95/165DPL-E/A Media has several advantages: high-speed, high-shear colloidal mixer causes a vortex flow to ensure mix quickly and evenly.

Features

WGP400/1000/95/165DPL-E/A Grout Mixer and Pump is a fully automatic grouting machine.

MIXER STATION

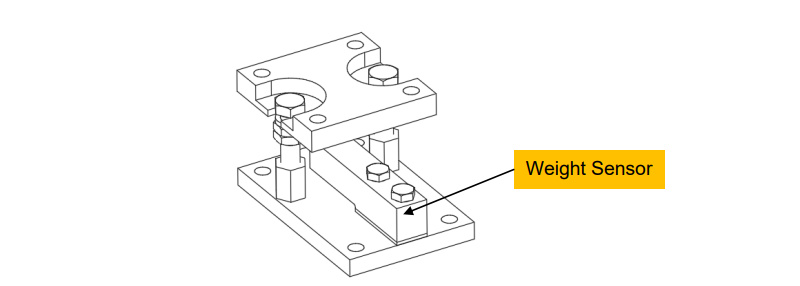

♦ 3 sets of stable weighing modules

♦ Lower charging material height for mixer

♦ High-speed colloidal grout mixer

♦ Smoothly outflow slurry through pneumatic pinch valve

♦ Precision of the ultrasonic liquid level meter

♦ PLC machine control

Visualization interface

Simple operation interface

Manual mode and fully automatic mode

Multiple formulations can be set up

GROUT PUMP STATION

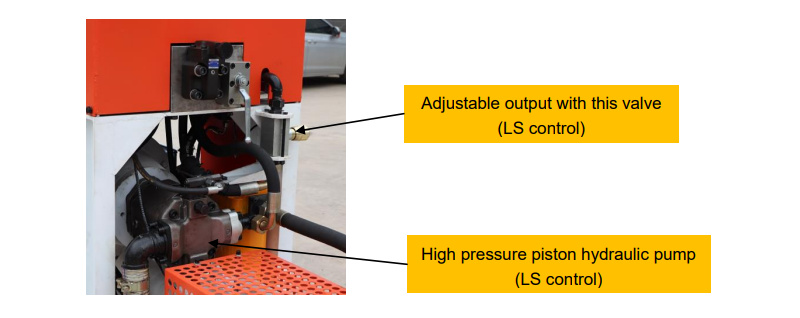

♦ Grouting pressure, displacement is step-less adjustable

♦ Simple structure, light weight, easy maintenance

♦ Double grouting plungers, continuous output flow with less pulse

♦ Less spare parts ensure low maintenance costs

♦ With the function of record and display grouting pump reciprocating times by a counter

♦ The motor has an overload protection function. Hydraulic system with oil temperature overheating protection

♦ Electric motor and hydraulic driven. Anytime, overpressure occurred, the hydraulic safety protection will be worked

Technical Parameter

| Specification (with Electric motor drive): | |||

|

Mixer Station 1.1 Pneumatic Pinch Valve: the slurry flows more smoothly; 1.2 Ultrasound Fluid Level Meter: height of agitator can be accurately measured; 1.3 PLC+Touch Screen: manual mode and fully automatic mode. Grout Pump Station 2.1 Grouting pressure, displacement is step-less adjustable; 2.2 Double grouting plungers, continuous output flow with less pulse; 2.3 With the function of record and display grouting pump reciprocating times by a counter; 2.4 The motor has an overload protection function; 2.5 Hydraulic system with oil temperature overheating protection; 2.6 Electric motor and hydraulic driven. Anytime, overpressure occurred, hydraulic safety protection will be worked. Trailer 3.1 With steering function; 3.2 Tripod height is adjustable. |

|||

|

Mixer Station |

|||

|

Mixer |

Effective Volume | 400L | |

|

Max. Mixing Capacity |

10m³/h |

||

|

Circulation Pump |

Motor Power |

11 Kw |

|

|

Rotating Speed |

1450 r/min |

||

|

Circulation Capacity |

1000L/min |

||

|

Agitator |

Effective Volume | 1000L | |

|

Motor Power |

3.0 Kw |

||

|

Water Supply System |

Motor Power |

4.0 Kw |

|

|

Displacement |

20 m³/h |

||

|

Head |

30 m |

||

| Air Supply System | Motor Power | 2.2 Kw | |

| Displacement | 0.25 m³/h | ||

| Control System | Mode | PLC | |

| Power | DC 24V | ||

| Grout Pump Station | |

| Plunger Diameter | 85mm |

| Plunger Stroke | 300mm |

| Adjustable Pressure | 0-16.5MPa |

| Adjustable Flow Rate | 0-95L/min |

| Discharge Pipe Size | G1 1/4" |

| Inlet Pipe Size | G2" |

| Oil Tank | 200L |

| Power Unit | 37Kw |

| Max. Grain Size | 2mm |

| Working Pressure | 16.5MPa |

| Dimension(L×W×H) without Screw Feeder@Weight | 3820×2280×2300mm@3750Kg |

| Screw Feeder | Output: 30t/h |

| Motor: 5.5Kw | |

| Dimension@Weight: 3700×600×800mm@280Kg | |

|

We also could accord to your demands to customize. All parameters are obtained by water test. |

|

Application

WGP400/1000/95/165DPL-E/A 95L/min 16.5MPa electric fully automatic grout mixer and pump are integrated with a screw feeder, mixing, agitator, and horizontal hydraulic pump. It is mainly used to be made such as cement slurry or bentonite slurry, etc., for injecting in the sub-soil for soil consolidation, piling, or even for long transport of material.

Compared with the traditional grout mixer and pump machine, WGP400/1000/95/165DPL-E/A Media has several advantages: high-speed, high-shear colloidal mixer causes a vortex flow to ensure mix quickly and evenly; Two pieces of high-pressure plungers to stabilize the consistency of the grouting flow; Grouting pressure and displacement is step-less adjustable; Added the automatic operation mode, which greatly improves the working efficiency. Besides, compact size and easy to operate. And it also takes up a small space. Therefore, this machine is widely used in mines, tunnels, culverts, subways, hydropower projects, underground projects, etc.

INQUIRY

Zhengzhou Wode Heavy Industry Co., Ltd.

-

Mobile Phone: +86-19913803800 -

E-mail: sales@wodetec.com -

Skype: Wode Equipment -

WhatsApp/Viber/Wechat: +86-19913803800 -

Tel: +86-371-55950656 -

Add: 20 Chuangyeavenue, GaoshanTown Industry Zone, Xingyang City, Zhengzhou, Henan Province, China

INQUIRY

If you have any questions, feedback or comments, please fill out the form below and we will reply you back as soon as possible.

HOT PRODUCTS

E-mail: sales@wodetec.com Consult