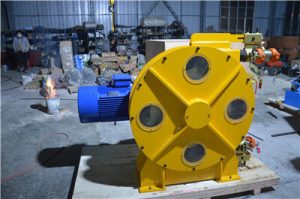

High Quality Wear Resistant Squeeze Industrial Peristaltic Hose Pump

High Quality Wear Resistant Squeeze Industrial Peristaltic Hose Pump are one of the fastest growing positive displacement pumps on the market. However, many are not yet familiar with the technical principles and benefits of pumps. In the past, most of these pumps were used only in the laboratory. However, after the redesign, Resistant Squeeze Industrial Peristaltic Hose Pump flow and pressure have improved. Hose pumps on the market today are successfully used in chemical process control and production applications.

High Quality Wear Resistant Squeeze Industrial Peristaltic Hose Pump popularity may be due to their design. This design uses a motor to drive and rotate a set of rollers. The drum runs on a soft pump tube, repeatedly compressing and ejecting. This compression creates a vacuum that draws the liquid out of the pump tube and completes the pumping process. Since the water supply section has only a pump pipe, maintenance and cleaning are easy and convenient.

High Quality Wear Resistant Squeeze Industrial Peristaltic Hose Pump design has many advantages, allowing the peristaltic pump to be adapted to a variety of complex and difficult application areas. The biggest benefits are:

- No pollution

The design and construction of the peristaltic hose pumps on the market ensure that the supplied fluid always flows into the pump tube. You can prevent the fluid from contaminating the pump. This is especially advantageous when transporting chemically corrosive or high-purity fluids. In transit, the fluid does not come into contact with gears, seal elements, diaphragm elements, or other moving parts, making it very easy to choose a pump that is chemically compatible with your particular solution.

2.Easy to operate

Peristaltic hose pumps for sale are also used to transport solutions that tend to settle or harden. In this case, there is no need to completely disassemble the part or clean or replace the pump tube.

- Reduce maintenance

Most peristaltic hose pumps require little maintenance to maintain good operating conditions. The pump tube should be replaced regularly during use to prevent leaks and reduced flow rates. The replacement process usually takes only a few seconds. Many pump designs have a high degree of protection. After transporting the dirty liquid, the pump tube can be removed and cleaned for quick and thorough cleaning.

- Strong self-priming ability

At startup, the perforated hose pump for sale draws liquid from the liquid source into the pump tube, thereby generating sufficient suction force, thereby eliminating the prefilling and filling process of the object, making the pump more flexible and pumping. Allows you to move freely.

If you are interested in the High Quality Wear Resistant Squeeze Industrial Peristaltic Hose Pump, please contact us! Email:sales@wodetec.com