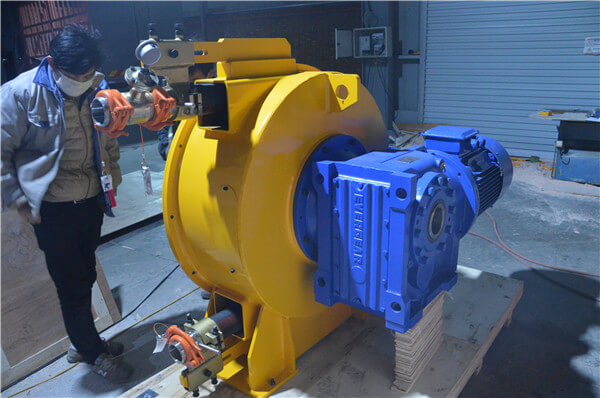

Manufacturer produces extrusion concrete peristaltic hose pump

In recent years, science and technology have developed rapidly, and the related knowledge of peristaltic pumps has been updated. Mining and heavy industry perturbation pumps were initially used in laboratory research, but are now widely used in mud pumps, food additive transport, mud transport, etc.

The operation of the manufacturer produces extrusion concrete peristaltic hose pump is the same as that of the human digestive system and can send gas, solids, and liquids. Manufacturer produces extrusion concrete peristaltic hose pump are widely used in the industrial field due to their high flow rate and high output pressure.

Advantages of manufacturer produces extrusion concrete peristaltic hose pump Applications:

1.The manufacturer produces extrusion concrete peristaltic hose pumpuse less water.

The manufacturer produces extrusion concrete peristaltic hose pump can circulate the slurry of SGS 1.6-1.8 and the solid content concentration can reach 80%. When the solid content of the slurry reaches 30%, the traditional central pump loses its efficiency. This limitation increases the process requirements for slurry pumps. : Can process 75 tons of ore per hour. Due to the inefficiency of mud pumps, at 65% solids, hose pumps can replace specially treated mud pumps, saving 100 million liters of water annually. For this reason, hose pumps use 25% less water than mud pumps.

2. The manufacturer produces extrusion concrete peristaltic hose pumps that consume less power.

In the same factory that processes 75 tonnes of ore per hour, the hose pump needs to consume 35 kW, while the same mud pump consumes 70 kW. With 50% or more energy savings, power consumption can be directly reduced. Power saving is a hotspot for many outdated mines, the cost of newly developed infrastructure and power inputs can be very high, deadlines are significantly delayed, and large environmental protests in non-mining industries. May lead to.

3.The manufacturer produces extrusion concrete peristaltic hose pump takes up less space.

Hose pumps improve offline efficiency and reduce the size of the entire plant. Slurry concentration is important for achieving the highest performance of the plant. Increasing solids can reduce the number of strainers, reduce initial investment costs, and reduce mining space.

4.The manufacturer produces extrusion concrete peristaltic hose pump that can reduce damage.

The manufacturer produces extrusion concrete peristaltic hose pump has a light pumping effect, and biological oxidation reaction technology minimizes damage to fragile biological cells. According to these requirements, the biooxidant process uses an organism to separate gold from the sulfide, reducing the amount of cyanide used and increasing the output.

5. The concrete peristaltic hose pump are low cost.

They reduce maintenance costs. The slurry is acidic or very abrasive. Therefore, the impellers used in traditional mud pumps are made of increasingly expensive non-standard materials, and their useful life is measured in days. Soft pumps can reduce mud damage and extend its useful life.