Why choose refractory pan mixer for mixing castable in steel plant

Compared with common concrete mixer, there are some outstanding features regards refractory pan mixer. Both the mixing speed and homogeneity are very high. Internal lining boards attached to prevent mixing material abrasion on drum, replaceable liners could continue to be used , low maintenance cost and long life. Combine mixing, electric and water into and organic whole, thoroughly implement of small automatic mixer. The bag cutting device is optional, the feeding height is comfortable, easy to use. The design is simple and easy with compact structure, internal cleaning is simple, convenient and easy to move. Three water lines could provide water from different direction, ensure that mix even materials and water.

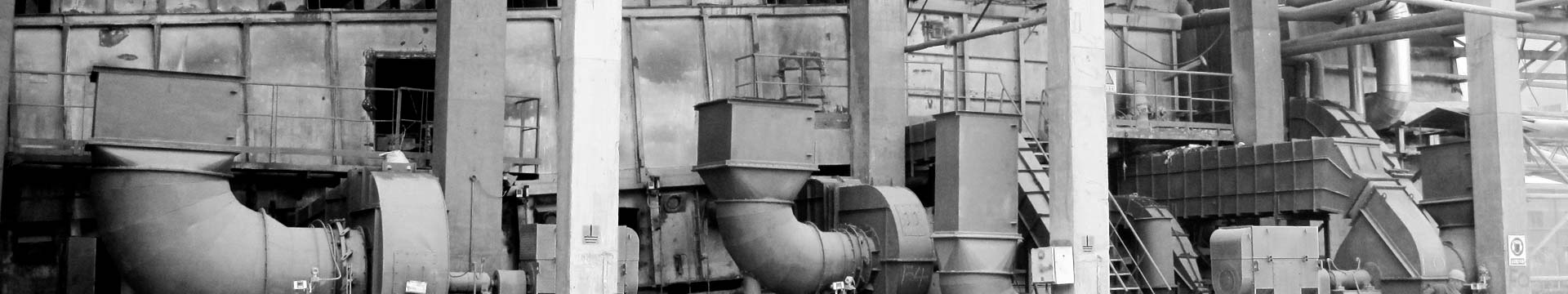

As refractory pan mixer manufacturer from China, Wode Equipment could provide different mixing capacity mixer for customers. High quality pan mixer is very suitable for mixing castable, refractory materials in steel plant, usually refractory pan mixer work together with wet refractory spraying machine.Above all, refractory pan mixer is very applied to the site construction, castable, refractory materials, etc. Especially, For WRM800 refractory pan mixer, we add ladder, operating platform, high pressure water washer device.

On the other hand, considering that WRM800 refractory pan mixer mixing capacity could be up to 800kg, need larger power motor, in order to protect electric motor when start, we add soft start device for WRM800 and WRM500 pan mixers.

In foreign, we have exported our pan mixer to many countries and received better feedback from customers. In China, we sell our pan mixer to some famous steel factory, like Baogang, Angang, Shougang etc.