The role of refractory pan mixers in the aluminum industry

The pan mixer of refractories plays an important role in the aluminum industry, which helps to produce and maintain the mixing and preparation of refractories used in aluminum melting furnaces and other high-temperature applications. These mixers are specially designed to deal with the unique characteristics and requirements of refractories.

1. Mixing refractories: The refractory pan mixer is used to mix various refractories, such as alumina, silica, magnesia, and other additives, to form a uniform mixture. This mixture is then used to line furnaces, crucibles, ladles, and other equipment used in the aluminum industry.

2. Consistent and uniform mixing: The pot design of these mixers ensures that refractories are thoroughly mixed, resulting in consistent and uniform composition. This is very important to maintain the desired characteristics and properties of refractory linings, such as high heat resistance, chemical stability, and mechanical strength.

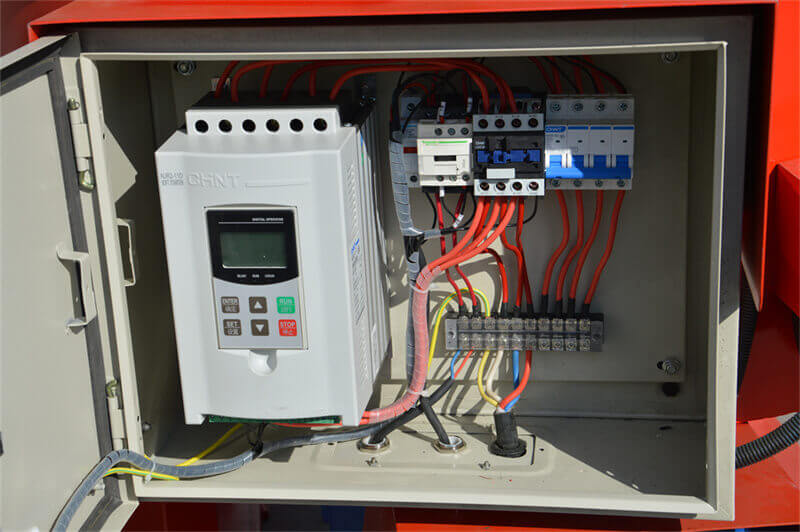

3. High mixing efficiency: The refractory pan mixer is equipped with powerful motors and solid mixing blades, which can effectively deal with the density and wear characteristics of refractories. This makes the mixing time faster and the productivity higher in the aluminum industry where time is critical.

4. Customizable mixing parameters: These mixers can flexibly adjust mixing parameters, such as rotational speed, mixing time, and inclination angle. This allows manufacturers to customize the mixing process to meet the specific requirements of different refractories and applications in the aluminum industry.

5. Durability and reliability: The refractory pan mixer is composed of heavy materials and components, which can withstand harsh working conditions and wear characteristics of refractory materials. They are designed for long-term use and require minimal maintenance to ensure uninterrupted production in the aluminum industry.

6. Safety features: Special safety features, such as an emergency stop button, interlocking system, and protective cover, are incorporated into the refractory pan mixer to ensure the safety of operators operating these machines. This is especially important in the aluminum industry, where high temperatures and abrasive materials can cause potential dangers.

In a word, the refractory pan mixer is indispensable in the aluminum industry, which is used to effectively and consistently mix refractories used in the production and maintenance of aluminum melting furnaces. The refractory pan mixer provides a necessary tool for manufacturing high-quality refractory lining and can withstand extreme conditions in the aluminum manufacturing process.