The benefits of using refractory pan mixers in the wastewater treatment industry

Are you in the wastewater treatment industry and looking for a reliable and efficient way to mix refractory materials? Look no further than a refractory pot blender. These refractory pan mixers in the wastewater treatment industry are designed to handle the unique challenges of mixing refractory materials, making them an essential tool for any wastewater treatment facility.

One of the main advantages of using refractory pan mixers is their ability to mix refractory materials thoroughly and evenly, ensuring a consistent and high-quality final product. This is particularly important in the wastewater treatment industry, where the performance and durability of refractory materials are critical to the efficient operation of treatment facilities.

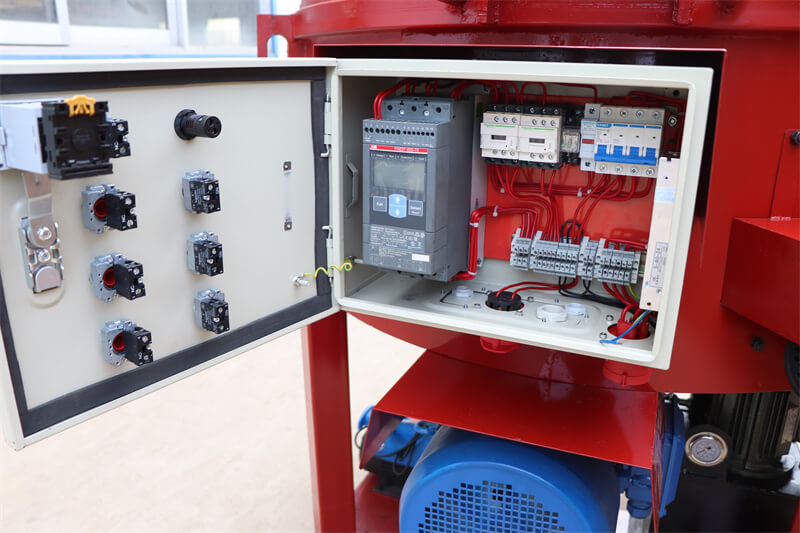

Additionally, refractory pan mixers are designed to withstand the harsh conditions commonly found in wastewater treatment facilities. These blenders are built with heavy-duty materials and components for durability. This means you can rely on the reliable operation of your refractory mixer, even in the most demanding environments.

Additionally, the refractory pan mixer is designed to be easy to use and maintain. Featuring user-friendly controls and easily accessible components, these mixers are easy to operate and maintain, reducing downtime and increasing plant productivity.

By investing in a refractory pot mixer for your wastewater treatment facility, you can benefit from improved mixing performance, durability and ease of use. This ultimately results in cost savings and improved operational efficiency.

If you’re ready to take refractory mixing to the next level, consider incorporating a refractory pan mixer into your wastewater treatment facility. Please contact us to get a product quote!