Refractory mixers are used in furnace lining, kiln, boiler and incinerator

In the construction industry, refractories play an important role in withstanding extreme temperatures and harsh conditions. These materials are used in various applications, including furnace lining, kiln, boiler and incinerator. In order to ensure the highest quality and durability of refractory products, it is very important to use reliable and efficient refractory mixers.

Refractory mixer is a kind of machine specially used for mixing refractories (such as cement, binder, aggregate and additives). They ensure the consistency and uniformity of the mixture, which is very important for obtaining the best performance and service life in refractory applications. These mixers are specially designed to deal with the unique properties of refractories, including their high density, wear resistance and heat resistance.

Type of refractory mixer:

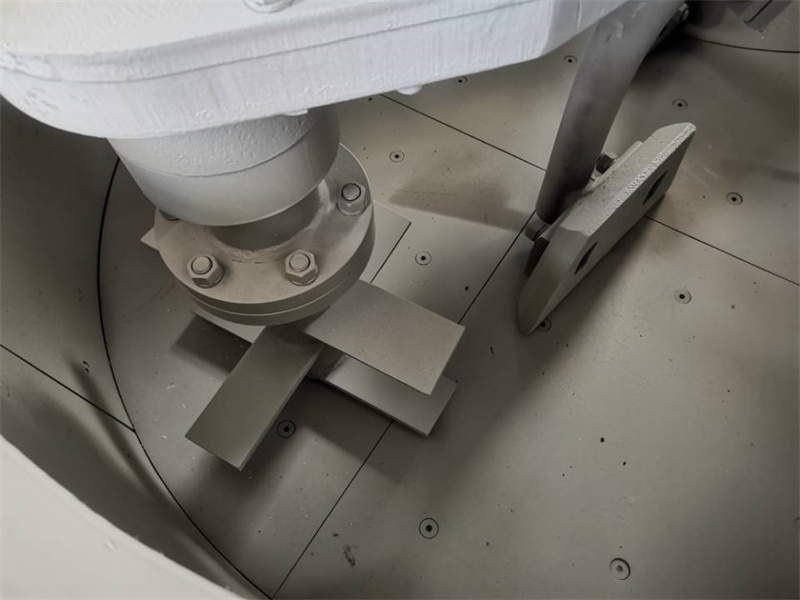

1. Disc mixer: The characteristic of this mixer is that the rotating disc with mixing blades can effectively mix refractories. They are usually used in small and medium-sized projects and are suitable for dry mixing and wet mixing processes. Disc mixers provide excellent mixing uniformity and are easy to clean and maintain.

2. Planetary mixers: These mixers use a rotating mixing arm, which rotates around the central axis and around its own axis at the same time. This dual movement ensures thorough mixing, making the planetary mixer an ideal choice for large-scale refractory production. They are efficient, can produce a consistent mixture, and can handle heavy loads.

3. Double-shaft mixer: Double-shaft mixer consists of two horizontal shafts with paddles or blades. These mixers provide a strong mixing action, ensuring a high degree of uniformity of the refractory mixture. They are suitable for large-scale projects and can handle dry mixing and wet mixing processes.

Advantages of refractory mixer:

1. Improve efficiency: The refractory mixer simplifies the mixing process, reduces the labor demand and saves time. Their professional design ensures rapid and thorough mixing, thus improving productivity and speeding up the completion of the project.

2. Consistent quality: These mixers ensure consistent mixing of refractories and minimize changes in composition and properties. This consistency translates into the improvement of product quality, the enhancement of performance and the reduction of material failure risk.

3. Durability and service life: The refractory mixer can withstand the wear of refractory materials and the high temperature during mixing. Its sturdy structure ensures durability and enables it to withstand heavy-duty use and long-term operation.

4. Customization option: Refractory mixer can be customized to meet specific project requirements, such as refractory type, mixing capacity and automation function. This flexibility allows greater adaptability and customization to meet the unique needs of different applications.

Refractory mixer is an indispensable tool for producing high-quality refractories. They offer many advantages, including higher efficiency, consistent quality, durability and customization options. Contact us for more product models and quotations!