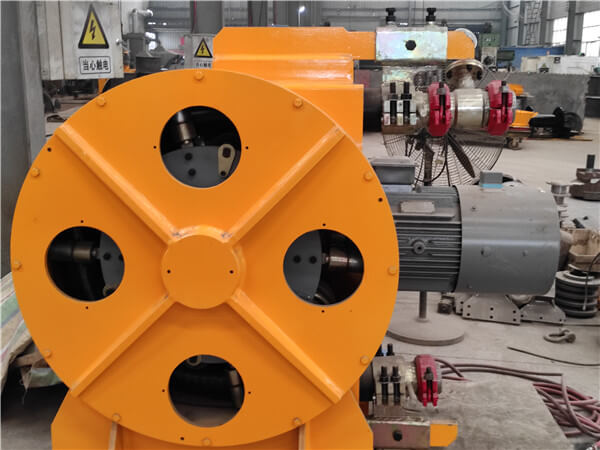

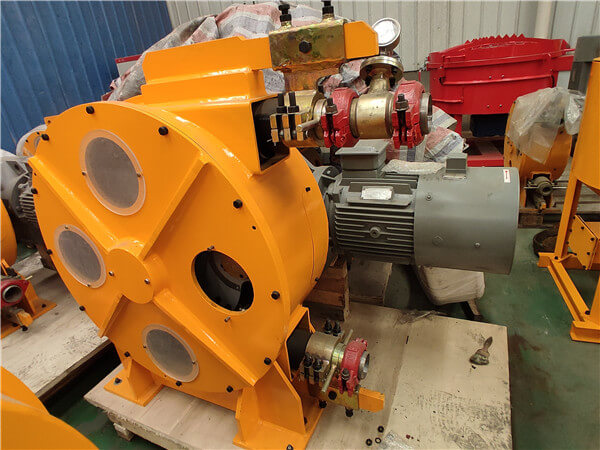

High abrasion resistance peristaltic hose pumpfor sale

2022-04-13 18:23:20

How about the high abrasion resistance peristaltic hose pump?

- Before disassembling the peristaltic pump, mark the left and right air chambers and liquid chambers respectively for subsequent reassembly.

- Connect the outlet pipe with a wrench, loosen the small clamp in the liquid chamber, remove the outlet pipe to check the valve ball and valve seat, remove the valve ball and valve seat, check for wear on other parts of the pump increase. Chemical corrosion and cracks.

Advantages of the high abrasion resistance peristaltic hose pump:

1.convenient installation, easy operation, and continuous long-time operation.

- The cutting sensitivity, abrasiveness, or gas-liquid-solid mixture of various fibers and slurries sent to the pump is selected and the diameter of the material is 4-6 mm or more.

- Can easily erode liquids in pumps, high viscosity, high-density liquids, and pasty liquids.

- Replace seals, gaskets, impeller rotors, stators, or traditional pump internal components for hose pumps.

- When the peristaltic hose pumpfor sale moves clockwise and clockwise, there is no backflow and siphon phenomenon, it has the function of an isolation valve. When it reverses, the liquid can be pumped out and sucked back.

- The pumped liquid is proportional to the rotation speed and can be measured accurately.

Applicable conditions for high abrasion peristaltic hose pump for sale:

- High abrasion resistance peristaltic hose pum is a positive displacement pump, the flow rate of the pump is determined by the output speed of the drive. Due to the structure and material of the pump, it is not easy to get too fast and the speed should be less than 50 rpm.

- If the process is a continuous operation, the actual flow rate should basically match the rated flow rate of the pump. If an operation is required, select a speed-adjustable pump for flow changes and do not use the pump’s rated flow for large flows.

- If the process is a gap operation and there are no quantitative requirements, the rated flow rate of the pump can be higher than the actually required flow rate. If there are quantitative requirements, the rated flow rate of the pump should basically match the actual flow rate. If the actual flow rate of the pump is higher than the required flow rate, you can add a bypass pipe to adjust it.

- The rated pressure of the pump refers to the working pressure of the pump equipped with a specific power motor. The actual working pressure of the pump is determined by the pipe resistance loss of the pump itself. Therefore, during operation, the actual working pressure of the pump must not exceed the rated pressure of a high flow peristaltic pump equipped with a rubber hose.

- Normal hose operating temperature is less than 100 ° C, taking into account the heat generated by moving parts during operation. Generally used for workers with material temperatures below 80 ° C. If the material temperature is allowed to reach 100 ° C under these conditions. For ventilation (or cooling), if the material temperature exceeds 100 ° C, a heat-resistant hose should be selected.

- Because the high abrasion resistance peristaltic hose pump is a type of pump, there is pulsation when carrying the material.

- High flow rate peristaltic pump with a rubber hose can run idle for a short time.

More details, please contact us! Email:sales@wodete.com